Cosmetics and Personal Care

Here the two important factors tend to be the anti-oxidant protection provided by the exine shell coupled with the ability of the finger or thumb or other pressure to release an encapsulated liquid from the exines onto such as fabric or the skin. The exine shells are a natural replacement for the plastic beads that have for many years been used in cosmetic, personal care and laundry products.

The encapsulated active ingredient may be applied to the skin in a cosmetic formulation and release from the exine shells onto the skin over a period of time achieved by continued rubbing. The encapsulated active ingredient in a cosmetic, personal care or laundry formulation may also be sprayed onto fabric or other surface and release achieved by pressure. However, depending on the encapsulation process a continuous diffusion from the exines (that act as a reservoir) can be achieved.

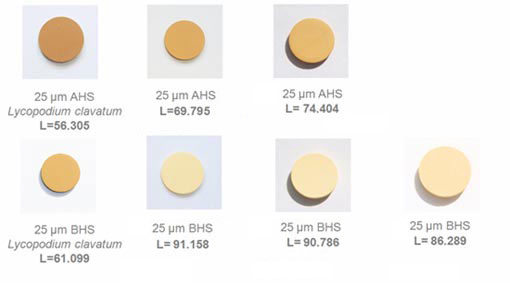

The encapsulated ingredients form a dry powder, which can be added to a cream or lotion. Several different powders can be used in a single product so for example, sun screen, sun tan and an aroma could be present in a sun lotion. The colour of the powder can be varied from chocolate-brown to light cream depending upon the application for which it is required.

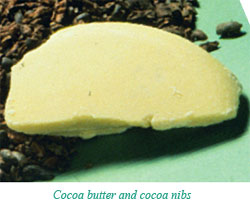

Where the active ingredient is volatile a co-encapsulating substance is required to block the pores in the exine shell or to form an inner or outer protective layer. In order to obtain effective release on application however, this substance must be easily broken or able to be pushed out. One possibility is cocoa butter which can easily be applied as a liquid during the filling procedure. It then becomes solid at ambient temperatures, but melts again when put on the skin. Rubbing will release both the cocoa butter and the active ingredients it is helping to contain.

Where the active ingredient is volatile a co-encapsulating substance is required to block the pores in the exine shell or to form an inner or outer protective layer. In order to obtain effective release on application however, this substance must be easily broken or able to be pushed out. One possibility is cocoa butter which can easily be applied as a liquid during the filling procedure. It then becomes solid at ambient temperatures, but melts again when put on the skin. Rubbing will release both the cocoa butter and the active ingredients it is helping to contain.

We have licensed our exine shell technology to a multi-national cosmetic ingredients company for use in the decorative cosmetics market. A variety of cosmetic formulations have been manufactured and cosmetic products incorporating our exine microcapsule technology were placed on the market late 2012.